Wed 14 January 2004 |

| Started the day deburing all the skin holes. As the control surface skins are very thin I did it all by hand, a single turn of the counter sink was plenty. Using the polystyrene from the shipping crates helps here to support the skin. |

|

| Then came smoothing of the edge of the skins. This is even more delicate due to the thin skins. |

|

| After using a file to remove the pressing marks, I ran the edging tool to remove the very sharp edge. Two passes were plenty. I only smoothed the three edges excluding the trailing edge. We will do that after the rudder has been put together for the final time (and then only very lightly). |

|

| Dad was meanwhile deburing and smoothing edges on all the stiffeners, these were then dimpled. |

|

| We then dimpled all of the spar components of the Rudder. With the two aft most rivets of the ribs we could not fit the vice dimple or yoke based dimple dies in so we just counter sunk them. I have no idea yet how we are going to set the rivets in these locations yet..... |

|

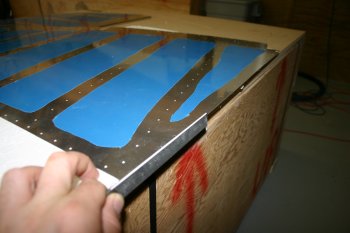

| The final part of the day was using the C frame dimpler. We setup some polystyrene and a piece of carpet to support the skins whilst we were dimpling. With two of us it only took about an hour to do both skins and they came out really well. |

|

| Most of the rudder is now prepared. A little more dimpling may be needed tomorrow and we need to work out how to counter sink the AEX wedge on the trailing edge. |

|