Tue 27 January 2004 |

| To start the day I did some clean up of some of the panel sub-structure. Filling a bit of time whilst we waited for the Avery FedEx order to arrive. |

|

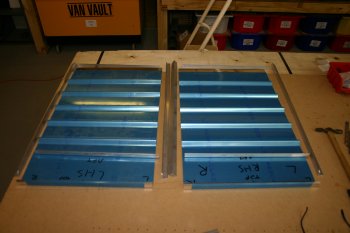

| The FedEx order with the rivet fan arrived mid-morning so I spent the rest of the day doing the seats. Firstly I continued to layout and setup the edge angles. |

|

| I set up a drill jig with the 5/16" distance and then started working through the drilling. All holes were completed at #40 and then later enlarged to #30s. |

|

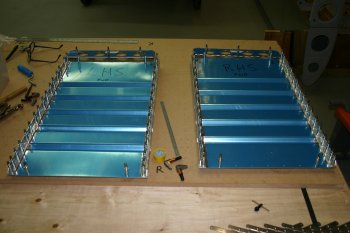

| Clamping the side angle is a little difficult as all the normal cleco methods don't have enough 'depth'. I ended up using old fashioned clamps. I took a bit of time over the line up and spacing checks as this is a more 'visible' part of the aircraft finish. |

|

| Once most of the #40 holes were drilled and the alignments checked then it was easy to enlarge to #30s. |

|

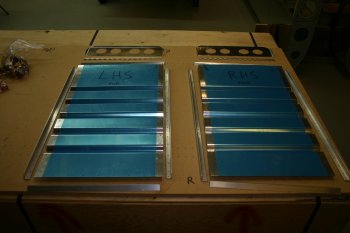

| Then finished the day by deburing and cleaning up the parts. Pretty much ready for priming although I still need to sort the upper and lower piano hinges. Hopefully complete it all tomorrow. |

|

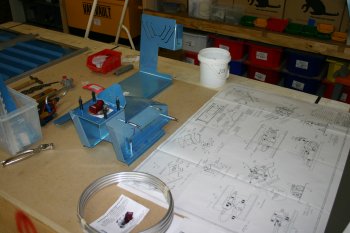

| Meanwhile in a galaxy not so far away, Dad was investigating the airflow fuel injection pump and trying to fathom the multiple funny bent lumps of tubing on the drawings. |

|

| After some initial head scratching the principles are now understood. Next was more deburring and edge finishing. |

|