Sat 31 January 2004 |

| First item of the day was drilling the other aileron for the attach brackets.

Then I put both the ailerons to one side, not completed as I've decided to use countersunk pop rivets to locate and hold the nutplates. However these need to be ordered with my next general order from Spruce / Wicks (whoever) and we can continue rigging without these nutplates being in place for the moment. |

|

| The next sub-assembly I decided to look at was the basic TruTrak servo installation. This is going to be installed in the right wing and will provide the control input for the autopilot.

The kit is fairly simple with a servo, two mounting brackets, a push rod and a spacer. It is a little frustrating that the 5 bolts, 5 washers and couple of nuts are not included in the US$2000+ kit. I guess I've got used to having a valid sub kit from manufactures, but it is frustrating to say the least to find something that can't be completed due to such simple problems AND will cost my US$40+ odd dollars just for the SHIPPING of the parts to NZ. There isn't even a callout for needed parts. I'm not the first person to complain about this and it seems a shame that what is meant to be a first class product is let down by something so trivial. |

|

| I installed the lower TruTrak bracket. Removed, drilled the upper bracket and reinstalled with the bellcrank.

I also removed, drilled and installed the bellcrank on the left wing. |

|

| Next up I started on the lower skin of the RHS wing. Normal process here, cleco'ing, drilling, deburring, dimpling etc.

First though with the QB wings you need to remove the 4 (yes four - don't ask me how I know!) pop rivets used for shipping. |

|

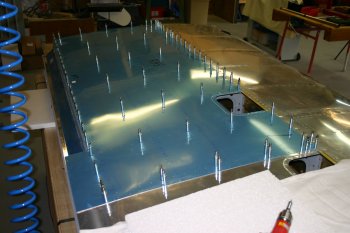

| All cleco'd up, I started in the mid wing and worked the cleco's aft and outboard. Needed some jiggling of the ribs in places. |

|

| Then the normal #40 drill processing....

I managed to finish the day with the skin uncleco'd and the ribs all deburred (top and bottom). Skin debur and dimple tomorrow after some socialising. |

|

| Meanwhile Dad spent the afternoon finishing the forward tunnel cover and heat baffle drilling. |

|

| Normal deal - drill, debur, dimple, and clean. |

|

| The partially finished parts (except for fitting and drilling to the fuselage) ready for priming. |

|