Tue 10 February 2004 |

| Dad started by sorting the left wing flap brace. The wing skin side needs to be countersunk. |

|

| Wing skin dimpling for the flush AD3's. |

|

| And the other wing skin..... |

|

| Then the day took a left turn. The professional spray company we are planning on using called in and we chatted about various priming options. Currently the paint shop is fairly quiet and it was suggested this week might be a good time for a first batch of large skin priming. Therefore we dropped everything, committed to being with them tomorrow afternoon with something to spray. We started digging around and deciding which bits we wanted to do. The obvious first choices were the VS, HS and lower outboard wing skins plus the panel sub-structure and a few other bits. However this meant we needed to finish working on some of these parts....... |

|

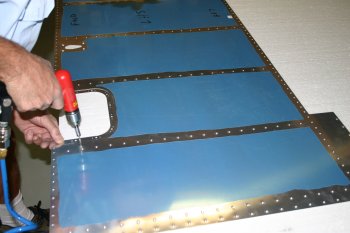

| We cleared the decks and Dad got stuck into finishing the wing skins. Not too bad, mainly access plate and general tidying. |

|

| Obviously the right wing needed doing as well for spraying. |

|

| The panel substructure doesn't really need to be done just yet, however we would like to try priming these part and see how it goes. We are also considering our options for within the cockpit space and are looking seriously at Anodising as a finishing option. |

|

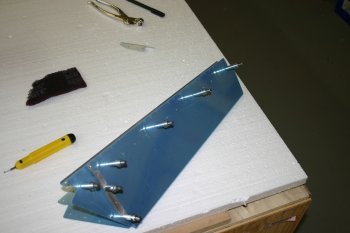

| The other part that I would like to get sprayed is the elevator trim tab skin. So I set to work match drilling the Z shaped stock. |

|

| The Z is then countersunk for the skin dimple and piano hinge below. |

|

| The finished parts of the trim tab - not yet with the 'interesting' tab folds. |

|

| The large skin parts ready for transport to the paint shop tomorrow. |

|

| We then spent the rest of the afternoon working through the elevator skins, prep'ing, smoothing, deburring, dimpling..... you get the idea.... Right side is done, left side to be finished tomorrow morning. |

|