Sun 22 February 2004 |

| First thing I finished the preparation that I could for the front wheel. The drawings for the nose wheel are better than the mains, however there is still a bit to be desired on the labelling / call outs. |

|

| Cross drilled the front leg mounting. |

|

| The cross bolt from the plan call outs is for a AN5-17A but it looks too long to me. I don't have to rush to make a decision but will probably get a 16A to replace it. |

|

| This is the brake disc / wheel pant support. The gap ended up being 1/4" rather than the 1/16" suggested, hence why the spacer were slightly larger (1/2") than the 13/32" suggested. |

|

| We then dis-assembled the main gear legs and re-oiled all the ground metal surfaces for long term storage until the new fuse arrives. |

|

| We are still without Pro-Seal / epoxy for the trailing edges, however I realised today multiple (most) parts of the rudder can be assembled without the trailing edge being completed. |

|

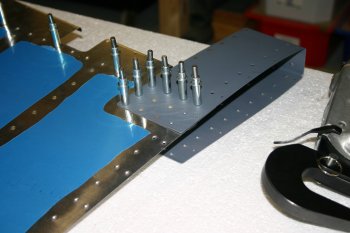

| The first stage is the skeleton structure. Making sure the reinforcement braces are the right side and right way round. |

|

| Then squeezer with the longeron yoke. No big issues, plenty of space / access. |

|

| A couple of the lower rivets required bucking. |

|

| Next up is the upper counter-weight. These had to all be bucked as the long nosed yoke wasn't long enough! |

|

| The lead counter weight needed to be significantly trimmed for the rivet shop heads. |

|

| After a bit of experimentation we found the rotary burr in the pillar drill worked well. |

|

| The installed weight, torqued up and ready for closing up. |

|

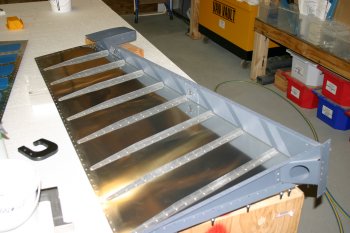

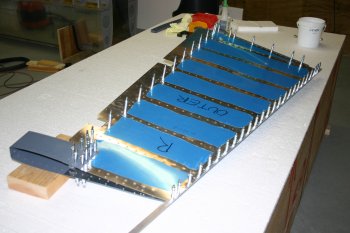

| We then moved onto the skins. This seems slightly counter intuitive to me, but the instructions definitely get us to do this before the AXE wedge pro-seal fun & games. So normal deal, cleco on and prep for riveting. |

|

| The upper overlapping skin needs a slight 'bevel' which isn't that easy to apply. After dimpling it is even worse..... Another occurrence of trying something for the first time where it will show. Seems to have come out all right, we will see how the skins finish up. |

|

| Six of the internal rivets can be set using the yoke, the remaining three will have to be bucked. |

|

| Bucking in that small cavity required some 'new' bucking bar, so Dad polished up another face of an existing bar. Grinder to get the first cut and then a large scotchbrite wheel. Steel eats the scotchbrite pretty quickly. |

|

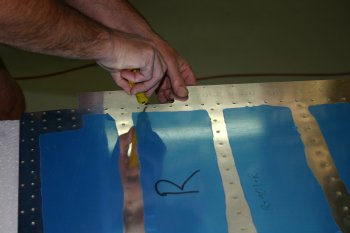

| We decided to mount the second skin before bucking the top. Also now is the time to remember to remove the internal blue plastic..... |

|

| The skins needed a bit of edge tidying, when we did them originally we were very tentative due to the thickness (or lack thereof) the sheet. Nothing serious just a few burrs on the edge that will be rolled.

.. |

|

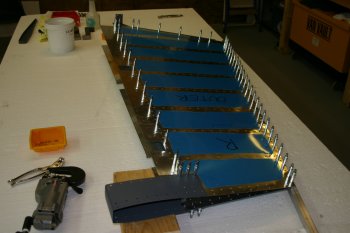

| Second skin cleco'd up plus the AXE wedge and angle support all setup (no pro-seal). We found the trailing edge needed a bit of cajoling to get everything lined up. If I was doing it again I think I would hold off the upper skins rivets until both skins are cleco'd together. |

|

| I set the upper squeezed rivets on the second side and left it there for the day. Tomorrow we will start on the bucking. Just need to find some pro-seal...... |

|