Mon 01 March 2004 |

| I started by sorting the brake horn drilling for the rudder pedals. After reviewing the instructions on Dan C site the solution was obvious (follow Dan's advice!). I hung the rudder pedal tubes on a couple of blocks and lined everything up. |

|

| Then using a small pilot drill scribed an arc on the plastic sheet. |

|

| Then it was easy to locate the centre of the 'lump' and find the intersection. As the pedal configuration is duplicated (eg P1 left and P2 left) I decided to match drill both horns at the same time. This was a mistake (see below), if you have dual brakes, mark the arc independently and treat each pedal separately. |

|

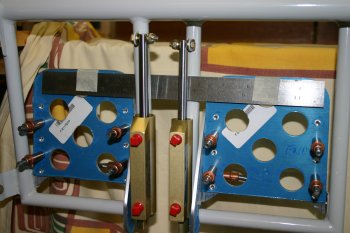

| The P1 (left seat) pedals. All nicely aligned and looks great. |

|

| The P2 (right seat) pedals, difficult to tell from the photo, but the pedals are at different angles at rest. Probably not a big thing from a flying perspective, but annoying never the less. I tried swapping the pedals / brake cylinders around but the error comes from the weldment being slight different P1 vs P2. One of the occassions to forget about the minor problem / mistake and move on. |

|

| As we plan to have the rudder pedal assemblies hard anodised I decided to take a bit of extra care with the surface finishing of the pedal cut outs. This is the sort of decision which is quick but the resultant work is multiple hours. First I had to find something that could be used to sand away an 1" hole, which took another 30 mins. |

|

| We ended up dressing down the ScotchBrite wheel down to about 15/16" and then taping medium grit paper to it. The result is a really nicely finished internal surface. Worth the extra time and effort. |

|

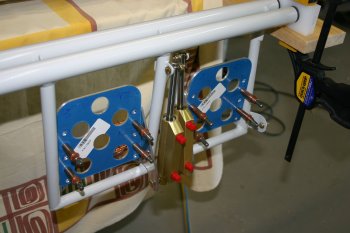

| All the rudder pedal parts ready to be sent off for anodising. Email's to be sent tonight, hopefully be able to get them done within a week or two. |

|

| Dad also managed to sort some of the preparation for the push rod / tubes. The cutting and drilling has already been done but the parts need permanent identification marks sorting and cleaning up, he used the tip of the small pilot drill to label 1,2,3 & 4 dots. |

|

| A tube rack was also fabricated to assist with handling and spraying. We will probably etch the inside and out, then prime the internals by sloshing primer up and down and then spray the exterior. Early finish today, Dad was out for the evening and completed a significant chunk of a steel frame for a new work bench. |

|