Mon 13 December 2004 |

| I started by fixing the wing / fuselage cover. I suspect these are going to be a constant bug-bear. |

|

| Dad worked on the brake line unions and fixings. The lower surface (fuselage skin) needs to clear the shoulder of the 45 degree union joints and the weldments is what it all tightens down onto. |

|

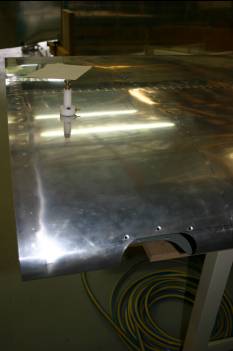

| Then I finished of the right wing nutplates. |

|

| Dad worked on the fuel line location. This is a two skin area on the 7A. The first thought was to drill through both skins. |

|

| However, I thought maybe a smaller hole on the inner skin might work well. |

|

| We discussed for a while and decided that just follow the instructions. If I was doing it again, I think a smaller whole on the inner skin would actually work better. |

|

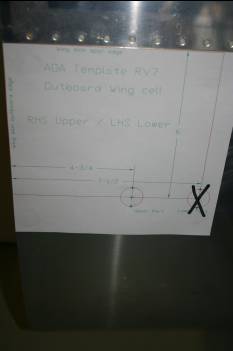

| One area that still has to be done is the Angle of Attack system.

This requires two ports that sense the upper and lower air pressure on the top / bottom of the wing surface.

The issue was that where the recommended location ended up just behind the duck works light location.

My concern was it the interrupted airflow might have affected the AOA readings.

I sent an email to Jim at AOA systems, and I moved onto something else. |

|

| Now don't laugh! - But, some of the more critical areas that we have been shaping and drilling over the past few days have ended up with no primer so a little touching up by hand seemed like a good idea..... Complete over kill, but why not! |

|

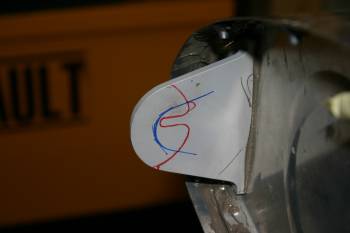

| Next up was the tank attach bracket drilling.

The blue line shows the 1/2" distance from the edge and the red line is the bracket that was drawn when the wings were attached. |

|

| The 1/4" hole is not tricky, just need to get it right! |

|

| The forward side of bracket then has the nutplate. |

|

| Dad continued with gear weldment and specifically the brake union. |

|

| I went back to the Left wing and did the attach bracket. |

|

| Then started looking at the wing tip. This will need significant shaping at the aft tip, I'm not sure what tools / methods to use yet. |

|

| I got a response from Jim to say as long as the locations are 2" ish clear of everything else, it is better to stick with the published position and then the pre-configured parameters should work. |

|

| The ports require #4 screws but getting the dimple sorted was a bit of a challenge. I ended up using a AD3 dimpler, and then pulling it down as needed. |

|

| Now todays question: We need to get multiple cables, air lines etc from one end of the wings to the other.

My intention is to use conduit, however it requires 13/16" hole the length of the wing, with the inboard lower skin already riveted. I see a number of options but not sure of the best, a question to the lists is

going out tonight...... |

|