Wed 29 December 2004 |

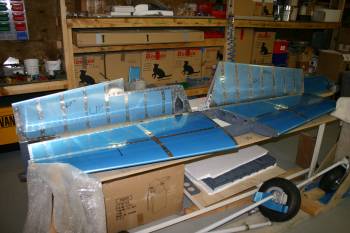

| The mounting of the elevators on the HS is pretty fiddly but otherwise not too hard, first looks were good, but it became obvious quickly that multiple on and off operations were going to be needed so we removed the HS to the bench. |

|

| The second observation was the RHS elevator horn seems to be at an angle to the center bearing (more later) |

|

| The bench was a good plan, generally we used shorter make up bolts during the test fitting, although a pair of long nosed pliers was still needed. |

|

| Early on the trimming of the HS skin was needed, we started with the lower surface and did the upper surface after the center bear drilling (see below). Normal type of drill, rough cut then file and finish. In round term it is just under an inch of skin from the trailing edge of the mid spar. |

|

| The alignment of the two elevators was a slow and iterative process. A half turn of the pivot knuckle changes the hinge point by 1/128". The center of bolt to spar is a min of 13/16" and a max of 7/8" - a whole 1/16" to play in (ie. about 3 different orientations)! Also the clearance of the rolled leading edge and horn bolt spacing all have to be taken into account. |

|

| Got there in the end with everything looking good. The HS lower spar flange needed a little additional trimming and the gap looked a bit one sided, but everything fitted snugly and rotated freely. |

|

| Dad made a bushing guide for the 1/4" bearing with a #40 drill center, fairly simple once everything is setup, just drill into each horn in turn. |

|

| Then it is open to 1/4", debur etc. |

|

| And re-assemble. Everything fitted well and all rotated without issue. |

|

| The problem is the RHS bearing to horn is still too large, the drawings state 3 washers max and it needs about 5! Not sure what - if anything went wrong, probably just the weldment. Email to VANs tonight, not sure if they are working over the festive season but hopefully we can get a solution and move on. Plenty of other things to do in the mean time. |

|

| During other moments during the day Dad also did the rear access plates for the fuse. |

|