Wed 05 January 2005 |

| I started for the lower elevator push rod, we had worked out that we needed the maximum length possible, I worked out it was exactly what VANs specified as the 'normal' length - suprise suprise..... |

|

| I tightened the harness fixtures. These were a problem with the QB fuse and needed redoing. |

|

| I also removed the control column system and removed some of the binding locations. |

|

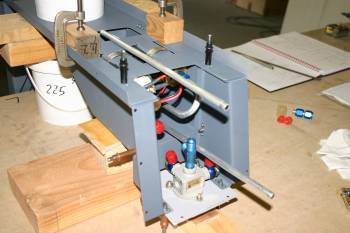

| I then moved on to the fuel system plumbing. An 'interesting' set of problems..... |

|

| After failing a few times (see right hand side :-) I manage to sort the first line from the valve to the filter inlet. |

|

| And got the remaining pipe work sorted comparatively quickly. |

|

| Then the modified base plate could be riveted to the cover panel |

|

| After a bit of manipulation everything fitted. |

|

| The final solution all looks good although only using bronze clecos rather than #8 screws for the moment. |

|

| Dad didn't get much time on the project today, but did manage to tweak some of the cover plate stand offs |

|

| and fitted them. |

|