Fri 26 August 2005 |

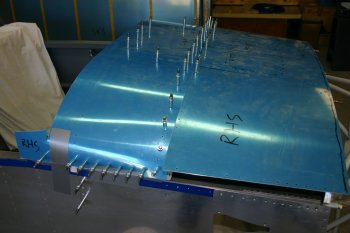

| First up - re-cleco'd the skins onto the frames. Reduced the gap to the minimum amount - 20 thou and reviewed where the holes were going to come. Decided edge distance was too small and re-lined everything with minimal edge distance that I was happy with. |

|

| Then drilled the pilot for the retaining pins. We used the bushing made for the elevator horn drilling - 1/4" O.D and #40 on the inside. |

|

| This gave us two pilots to work from. Both were slight aft of the centre line of the goose neck. |

|

| Then we opened up to 27/32" by drill. It seems the material may be a little softer than some of the other AL in the project. The drill kept grabbing and was hard work. Finished the hole with a 3/8 reamer and then used the vice to squeeze the bushings into place. |

|

| Re-assembled the latch mechinism and trialed the action. Found a number of problems - firstly the LHS (right in the picture) was still too tight (see yesterday's entries about the bad rivet squeeze) - therefore I had to re-drill out for the second time the two upper AN426 rivets and re-set after bending the ribs further. Secondly the weather strip was too big in places and needed to be reduced two enable the frame to rotate cleanly. |

|

| After various tweaking - everything is working. Latch mechinism is still difficult to use for mounting - but removing is nice easy! Finished the day re-clecoing the skins on and checking clearances - probably ended up with about 40 thou across the whole width. |

|