Sat 24 September 2005 |

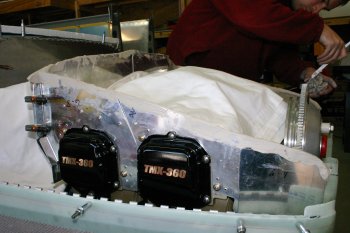

| Another day on the baffles.... This is the rear baffle. |

|

| The front RHS looking back over #2 & #4 cylinder. |

|

| The front LHS looking over #1 & #3. |

|

| Then we moved onto the baffle / cowl gap, this is meant to be between 3/8" and 1/2" - as I'm seriously thinking about a plenum so want as much height as I can get.. |

|

| A local pottery club had a source of fine grain clay. |

|

| It is sort of similar to putty to work with and I put a bead of clay along the top of the baffles. |

|

| Then the upper cowl was fixed into place and pressed firmly down. |

|

| That provided the shape of the cowl, but it was difficult to provide a shape line due to the 'width' of the clay. |

|

| Therefore this was trimmed along one edge. |

|

| |

|

| It was then easy to mark a pre-set distance down around all of the baffle. |

|

| Remove all the clay, wash and dry |

|

| A Dad worked around the edges with a 'flexi-curve' to produce a reference line which should have 3/8" clearance all round. |

|

| The LHS floor baffle, needs bending and trimming, I used the cardboard template method again. |

|

| More trimming and bending. |

|

| The resulting baffle part looks good, although it will probably need more of a downward bend, more refinement can be completed as needed. |

|