Sun 30 October 2005 |

| Dad started with a simple riveting job, getting the lower assembles for the arm rests together. |

|

| Using some J section two lengths were pre-drilled as upper surface braces. |

|

| The stiffener was positioned mid way between the two side surfaces at the forward end and about 2/3rds of the way in from the rear end - this seemed to provide the best support. |

|

| Then match drilled the J section to the upper arm rest surface. |

|

| The finished sub-assembly. Just top-coat and pop rivets / skin rivets to complete. That can be left until later. |

|

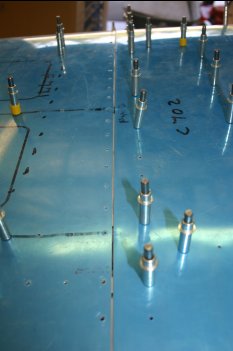

| I continued with the canopy frame. The braces were re-cleco'd and I drilled the skin locations to #41. |

|

| Then it was re-aligning the canopy frame back on the fuselage. The 'floppy' rear center structure makes it hard to get good alignment and a new temporary wooden plate was made which works well. |

|

| The forward gap between the upper skin and the canopy skin is very tight. This is good from a sealing perspective / rain handling - however the canopy needs to be able to be opened to get IN the aircraft! Current plan is to continue as needed and trim the canopy skin later once everything is riveted together. |

|

| The remainder of the afternoon was spent making ties and drilling them to the outboard braces. Fiddly, simple stuff. |

|

Also a number of other areas being thought about.

Exterior paint wise, I was planning on white with, dark blue / black on the belly and red tips for high-visibility.

Having thought about things a bit more, one idea that is now getting serious consideration is for a simple polished

main structure and just painting the cowl, fibreglass sections and tips. A rather different look if nothing else.

Then it is a choice on colour - new front runner is black (maybe metallic ($$$)) for large areas like the cowl and wheel pants plus (rescue or VANs) yellow for the tips -

this might sound like a 'wild' idea but has some benefits.

- it is the lightest option available,

- it is one of the cheapest options,

- we can always get a paint job later, and the tips will already be done.

Dad, also started work on a base plate for the milling machine which we will need for the access panels - more tomorrow.

| |