Wed 02 November 2005 |

| First up was get the canopy out in the sun to absorb the heat. We want 25C ish ambient temp to help prevent cracking / handling issues with the plexiglass. |

|

| Whilst we waited, we started looking at the static pressure lines. We will have two static sources, one in the traditional location and one on the heated pitot head in the left wing. The main challenge is the routing of the tube through the F-705 bulkhead. The 'normal' route is just below the longeron. |

|

| This is the problem - the angle bracket that supports the underside of the roll bar and canopy pegs needs an 1/4" minimum hole just to the left of the 'middle' two rivets. The other option is to route the tube lower and through the arm rest area and further forward. More thought needed. |

|

| In the mean time Dad continued with the rear drilling / layout fro the pop-rivets. |

|

| By about 2pm the sun had done its thing and the canopy was warm to touch. After more thought I decided to go for a 'bigger' initial cut and see how it panned out. Note: here I didn't have a glove on the left hand - BAD idea.... |

|

| With a glove (the hot plexi-chippings don't hurt this way) I worked around the front section. I took a couple of passes and generally moved the cutting towards myself. The hand combination was steadied by the outer edge. Worked well. |

|

| The result - a quick sandpaper around the top and bottom edges and ready for the next stage. |

|

| This worked EXTREMELY well, the canopy fitted almost all the way around the front edge first time. Next we put the rear upper fuselage skin on and roughed a line for the rear window. |

|

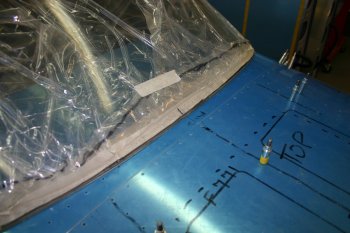

| This allowed us to calculate and mark a conservative rear cut line that was more than the trim I was expecting (and marked) yesterday. The marking is a slow process of pealing the protective cover back, re-taping, re-marking and then repeating for the other side. |

|

| This is the underside marked up for the side and rear edges, before the second cut. |

|

| Post second cut the whole canopy 'fits'. |

|

| The front is slightly forward of its final location (about 1/2") and is fitting the contour of the forward deck really nicely. |

|

| The rear is slight aft of its final location (extra 3/8"). |

|

| and the canopy is resting on the sides of the roll bar and about 1/4" - 1/2" clear in the centre - generally very good. |

|

| Now at this point we had to pinch ourselves. Most builders seem to take a long time to get things, after much - we must need to do more type thoughts I decided we really were ready to mark the cut for the canopy split. More protective film splitting, masking and taping. |

|

| Then it is the same deal on the under side. |

|

| The gap between the green masking tape is the cut line and is eyeballed to be roughly a cutting disk width. |

|

| Now at this point we could have continued and made the 3rd cut for the day - the canopy split, but the temperature was cooling down quickly and it was past 6pm (our pseudo cut off for 'big' decisions). Therefore we decided discretion was the best option and we will sleep on it and do it tomorrow if the weather is good. All in all a very good day - canopy split is another big milestone and it is now close. Still lots to do on the project but I think light is beginning to appear at the end of the process. Electrics / avionics is the BIG piece left, but lots of other stuff to do also. | |