Tue 08 November 2005 |

| Whilst it was cool this morning, Dad did a few Pro-seal misc jobs. The static rivets seemed like a good idea, goo and pull. |

|

| The fuel vents needed a mesh glued. |

|

| And the brake reservoir to the firewall. Also the lower cowl aft hinge was goo'd and riveted to the fuselage. |

|

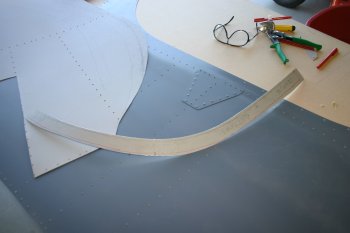

| Mean while I started making the spacer washer for the rear window. This will provide the inside part of the AL / plexi-glass / AL sandwich |

|

| Then with the temps getting warm again, I used the cut-off wheel to remove the side mouldings on the forward canopy. Interestingly the LHS has significantly less 'spare' material than the right. I don't think it will be an issue but I'm glad we didn't get over ambitious. |

|

| After remarking the front edge to a 'second cut' we let the sun warm everything and used first the cut-off wheel for a rough cut. |

|

| and then the hand held belt sander to get an accurate / smooth line. |

|

| This worked really well, you can see here we have left the edge of the plexi square to the skin, not the plexi surface. This seems to provide a better shape to the canopy foredeck. Our current thinking is to use a bead of fibreglass flox along the front and then blend the shape for a nice smooth finish. |

|

| Also received today was the FADEC 'fix' from Aerosance. I'm still rather disappointed with the lack of communication / the current "solution", more discussions needed. |

|