Tue 22 November 2005 |

| Whilst continuing to wait for other parts to be delivered and with some fibre-glass confidence from a couple of days ago, we found something new to focus on. All the empennage tips are made from fibre-glass and need to be blind-riveted to main structure. After completing the drilling we counter sunk the tips and dimpled the appropriate locations. |

|

| The inside of the elevators ribs in particular are very tight with the tips. 'Next time' I would trim them back before riveting. We just reshaped the tips slightly and moved on.... |

|

| Then I masked up all the edges 1/2" away - this will be used to feather the micro-balloons down to provide a neat straight edge. I used a piece of masking tape as the base layer and electric tape as the main 'protection'. A good scuff / sand roughens the surfaces to help the silica / epoxy past stick. I also trimmed the forward edge of the lead counter weights which had been missed to date. |

|

| We worked on all three tips at the same time - the top rudder and the two elevator tips (outboard). |

|

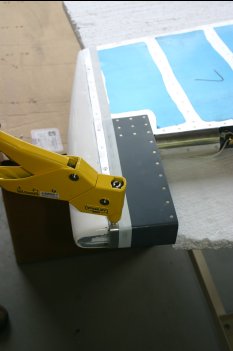

| Then with a silica/epoxy paste mixed and smeared over the contact surface it was cleco and pop-rivet everything. We found the pop-rivets need a bit 'extra' for counter-sinking to get a better flush finish. |

|

| After an hour or so everything was complete and the epoxy was starting to harden pretty quickly. There is definitely a point in the process when it is the 'right' time to stop. |

|

| With the elevator aft most rivets we ended up using AD3 blind rivets - even then it was really tight. |

|