Wed 23 November 2005 |

| Today we continued with the fibre-glass work. The silica paste over the lead weights work well, after a bit of light sanding / shaping we were ready for the next step. |

|

| A single pump of resin / hardener plus 5ml of micro balloons provides a nice thin ish paste for filling with. |

|

| Apply liberally and cover everything in a thin covering - this will then be sanded off once cured. |

|

| The overall process worked OK, the paste thickened slightly after about 15 mins and was a bit like 'cake icing sugar' in texture. Again it is quit whilst we are ahead. |

|

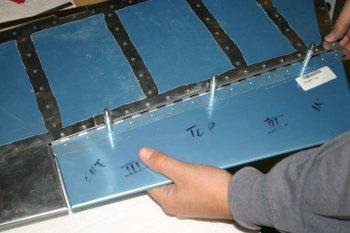

| Still looking for things to do - we were left with the THIRD elevator trim tab. The previous results have been patchy - the second attempt was OK but the alignment of the edges and hinge wasn't great. This time we decided to do things slightly differently, instead of bending the end tabs after 'crimping' the trailing edge we removed the lower tabs and will re-make these later. |

|

| Then we pre-bent the upper tabs. |

|

| This was the result ready for the bending brake. |

|

| With the brake we held the front edge and 'with confidence' flattened it. Worked well, maybe slight pinched but good enough. |

|

| Then it was process the mini-spar etc, the hinge pin alignment look OK but it was getting late so we didn't drill too much. That can wait for a fresh review tomorrow. All in all a good productive day, and hopefully tomorrow should be delivery day - lots of bits, lots of options on next steps. |

|