Thu 01 December 2005 |

| With a fresh mind, we restarted the cowl work. First up was getting a repeatable position for the front of the upper cowl. This was done via two 'precision cut' supports. |

|

| Then the new rear cut line could be marked - I used the same method as we have developed for the canopy work. Masking tape plus sharpie line. This new rear edge allows the front to come up and back a little which helps the 'planar' problem at the front and obviously helps the height problem. |

|

| The handheld band sander was used - it seems to result in a straighter edge than hand sanding large changes. |

|

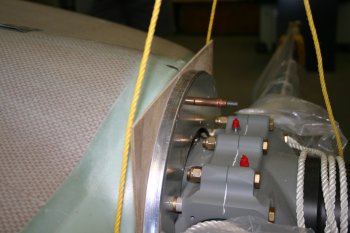

| Then after the upper cowl was 'getting there' the lower cowl was attached. The problem was then holding the upper cowl at the right height. A cord sling from the roof rafters worked well. |

|

| Rather than using the hinge (which can move fore and aft) a single tie was sorted in the center rear location and the forward center line could be matched on the spinner plate. |

|

| Then the old hinge joint was used to get a rough idea on the lower cowl position. The summary was the RHS was good the LHS was not quite there. |

|

| Therefore we went round all four side edges and straightened / levelled them. This has the side impact of helping the rear of the lower cowl come upward slight which helps reduce the rear gap and spinner alignment. |

|