Sat 17 December 2005 |

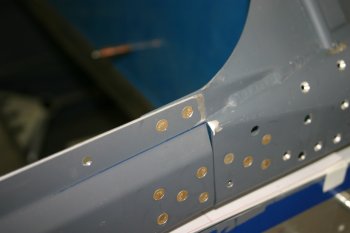

| Today was spent finishing the canopy frame drilling. First up was the rear join plate. |

|

| I then moved onto the side rails. These locations need to be countersunk for the #40 dimples on the side skins. The mistake I made was the microstop was setup for #6 dimples not #40 dimples. I focused on the bad 'chattering' of the countersink, rather than the wrong size! |

|

| After cursing and kicking myself for such a stupid mistake I continued with the others with a correct setting. After a bit of thought, I think the simplest recovery will be to use some fibreglass resin / silca mix on the 4 locations and redrill / rivet after setting. It is mainly cosmetic so I don't think it will be a big problem - just a stupid mistake. |

|

| Also sorted the AD4 rivets for the canopy frame / side rail tabs. |

|

| The forward canopy skin needs trimming for the side rails - snips for the first cut. The upper lines will probably need trimming also - but I'll wait until everything is re-cleco'd up. |

|

| Then it was skin prep work. The side skins and forward skin was deburred (both sides), dimpled and have a turn of the countersink. Repetitive process - but not hard. |

|

| The canopy skin also needed some C-frame work which Dad leant a hand with. |

|

| The final drill / prep work was the canopy frame tube. I started using a microstopped piloted #30 countersink, but the holes generated were awful and I'm concerned will be too big for the CS4-4 pop-rivets - I just decided to stop for today and revisit tomorrow. |

|