Fri 06 January 2006 |

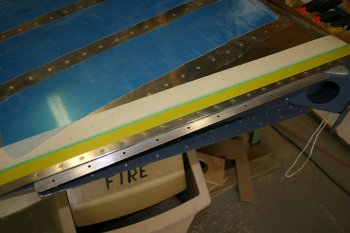

| Continuing with other things, I deburred and dimpled the wing skins for the tips. |

|

| If you are building - don't follow my lead here - the 'correct' method for the nutplates on the wing tips is to have the rivet going through the tip along with the backing strip. I've already riveted the nutplates to the backing strip - therefore I'm just going to use resin / silica flox as a glue. The strength comes from the spreading of the load so I'm not too concerned. |

|

| So a large-ish batch of resin work, scuffed all the parts and cleaned with acetone. |

|

| With the first batch of resin the mixture seemed more 'stringy' than usual - not sure why, so I focused on the wing tips rather than other areas. Basically a thin layer and then fully cleco'd the #6 screw locations. |

|

| With the next batch being a more normal mixture, I started with the rudder lower tip. |

|

| We found having the rudder vertical and sliding on the tip from above worked well. Then laying on its side for the pop-rivetting. |

|

| Continuing with the other side of the wing tips I finished the LHS completely, but still have the lower RHS strip to do. With that only being a 'half-batch' I decided to wait. Tomorrow hopefully I can complete that and do some more micro-balloons for the rudder tips. |

|