Wed 18 January 2006 |

| Started with a quick removal of the panel and support structures - still not sure how to mount everything whilst keeping it neat, simple and light. |

|

| With the temperatures well down (16C ish) I did some experimenting with fibreglass. One of the remaining challenges is the transition between the cowl and the plenum - particually on the upper surface. One idea is for a new inlet structure, so I tried making a 4" cylinder from 3 layers of 6oz BID. Layup went pretty well, the net result wasn't that great - see below. |

|

| Whilst I was in the fibreglass mode, I continued with another layer of micro-balloons on the upper cowl. |

|

| This time I used a really fresh mixture - which definetely helps although I'm still a bit unsure of how much to leave. Currently I'm squeegying (SP!) everything off and just leaving a thin film. I'll sand back tomorrow and see how it works. |

|

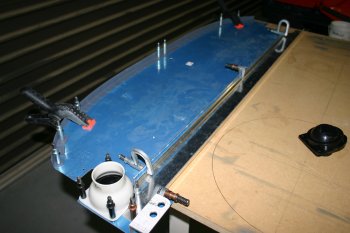

| Dad continued with shaping / cutting / drilling the empennage fairing / HS cover plates, slow iterative work. |

|

| |

|

| The rear cutout seems to be about right - just need to check clearances. |

|

| I spent the last hour or so, trying to extract the forma from the fibreglass test. I ended up running a piece of .032" material between the surfaces and then splitting the pipe from inside. Finally managed to extract the forma. The peel-ply didn't work that well, the outer layer had become saturated, this meant it was impossible to remove. I used a couple of plugs to re-expand the forma and left to cure abit more.... |

|