Fri 27 January 2006 |

| Short version - sanded, tried, failed, went for pizza & beer. Longer version... I started by removing the peel-ply - this worked really well and the shape looked better than I expected. |

|

| The front outboard corners will need the most work but that should be fine. |

|

| This is the result of the peel-ply where is worked really well - smooth and easy to sand and prep further. |

|

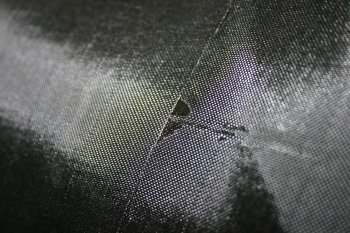

| This is not quite as good - I didn't squeegy enough of the resin through and ridges were still left - this results in a resin ridge which then needs to be sanded down / out. |

|

| The next 4 hours of so was spent sanding down the ridges to smooth the contours and rough the surface for the next step. Hard slow work, and the temps were getting into the mid 30C's. |

|

| To try and reduce the 'joins' between the peel-ply, Dad cut a single piece cover for the next session, along with a 'final' piece of 2oz cloth that covers most of the section (just the rear ears missing) |

|

| Further sanding of the edges back to the electrical tape to get the right shape worked well, just slow and hot.... |

|

| To try and reduce the 'ridges' on the peel-ply, Dad ironed it - worked well. |

|

| More sanding and shaping - everything coming together well. |

|

| Then re-applied a new layer of electrical tape / masking tape. |

|

| And trimmed / shaped the peel-ply and 2oz ply. |

|

| We then tried another fibreglass session, I added a little neat resin to the work area and prep'ed some more flox, however the flox was too stiff and setting quickly. |

|

| We ended up aborting the glass session - the pot of resin was too hot to hold (estimate of around 60-70C). Obviously the resin was reacting very quickly and the exothermic heat (we assume) was making it too difficult to use and the flox was slipping off the wet resin. We wiped everything down and quit for the day. I'm not sure WHY we had so much of a problem - I can only assume it was to do with the ambient temperature (mid 30C's / mid 90F's) - next time we will do fibreglass in the morning when it is cooler! |

|