Sat 28 January 2006 |

| A quick rub down and roughening of the resin surface ready for the final glass ply. |

|

| The flox to help build up the transition between the plexi and skin surfaces - fairly stiff but still workable. |

|

| I used a piece of masking tape to edge the upper line - worked well, removed before glass ply was positioned. |

|

| Plastic ice-cream container lids seem to make the best squeegy's at the moment. |

|

| The flox profile before tape removal and glass ply - you can see the central transition in particular is much smoother. |

|

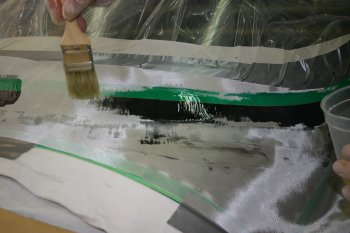

| The 2oz ply went on well and brushing on the clear resin allowed everything to seat and the green electrical tape comes through clearly. |

|

| Generally the upper line was sorted first and then the forward edge. The flox resin area was left until last. |

|

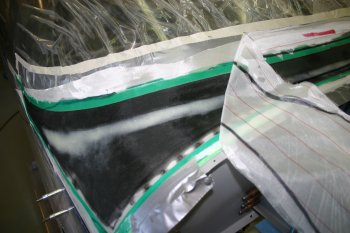

| The final product, after more brushing and squeegy the ply down. |

|

| and the peel-ply added and brushed down with more resin. I just managed to get the glass and peel-ply to fit over the whole surface (including the tail ears) which was a bonus. |

|

| The new lines - everything was setting pretty quickly today as the temps rose progressively through the day, high of 36C in the shed. |

|

| |

|

| We did some misc bits for a couple of hours and had a visitors to show round, before I decided the peel-ply was set enough and probably should be removed. It all removed cleanly, but we had to be careful around the edges to prevent it pulling the glass off the skin. |

|

| Although the temps were high, we continued with the resin work, focussing on the HS tips / elevator counter balances. |

|

| Using a microballoon based thickish mix, we layered the mix on and let gravity and surface tension help the levelling process. |

|

| The peel-ply with baking sheet and AL plate with a couple of bucking bars for pressure. We will see tomorrow if this has worked, but hopefully a smooth / flat surface will be left - in theory! |

|

| The HS tips were pop-riveted on with flox under the joint and a small amount of micro-balloons was added for the initial filling / shaping. |

|

| The remainder of the resin was used to fill the glass work on the canopy fairing. |

|

| This is going to need a lot more work, but the first layer can cure over night, an hopefully tomorrow afternoon I can start shaping it a bit. |

|

| Also been emailing with GRT and Stein - today got confirmation that the GRT units are nearly ready to ship. All systems are now go, so hopefully within a few weeks we should have our avionics. Still not sure about the layout yet, and some decisions to be made / information collected, but at least it is progress...... | |