Thu 02 February 2006 |

| Dad de-rigged the rear roll bar and also sorted some trimming of the strike plates - these have been opened up slightly outboard which now aligns nicely with the longeron covers. |

|

| Also the quadrant components needed some development - we are shortening the lever length by about 1", so the pivot and the actuation point needed to be relocated. Also the Red 'mixture' control was rubbed down and painted Blue for the prop control (being FADEC and not having any manual mixture control) |

|

| Nuplex delivery arrived mid morning - good service, ordered Tue morning, here Thr morning.... |

|

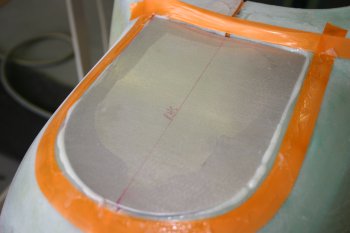

| I continued with the cowl / plenum work. This was the result from yesterday, it was OK, but not really as flat as I wanted. After various options being considered we decided there was probably a better way. |

|

| Therefore I cut and ripped off the glass from yesterday - even though it had only had 12 ish hours to cure, it was already pretty tough. The glass ply came away OK, leaving a resin layer bonded to the original cowl. |

|

| After lots of sanding I got back to the starting point, ready to try again. |

|

| With the temps back up in the high 20Cs we did the rear canopy screws. These have been changed to plain bright stainless #6 screws. I was hoping to use blacked stainless but I seem unable to get 100degree counter sunk black stainless screws, so - move on - fit for flight..... |

|

| Then back to the cowl, I made two metal supports and rebated the cowl to take them. |

|

| Then a good scuff of the AL sheet (palm sander plus scotchbrite pads work well) ready for silca floxing. |

|

| A generous layer of flox and then bedded down the AL sheets. |

|

| After a bit of tidying, pressure applied from the top and left to set overnight. |

|

| Other things going on today include more planning / organising of electrical parts / bits from the USA - not difficult, just logistics and time consuming. | |