Fri 17 February 2006 |

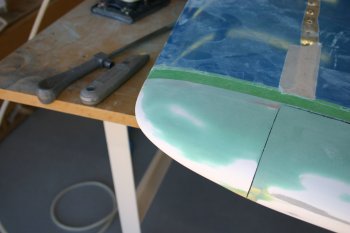

| Started off sanding down the lower surface of the elevator / HS. The final profile looks good, with the elevator in-trail the transition between the HS and control surface is very smooth. At this point however the two parts are still joined - not very useful as an elevator! |

|

| I used a pad saw plus knife to work along the original gap and then removed the hinge bolts - two parts came away neatly - then lots of edge tidying. I'll need to remove more of the HS tips at some point to get the 1/8" clearance, but I'll wait until I've done the work on the elevator counter weights. Surface wise it is probably ready of EP filler / primer. |

|

| Dad spent most of the day in the cockpit areas. Some of the original interior paint spraying didn't work that well and needed to be cleaned and rub down again. |

|

| The side cover plates for the spar bulkheads were pop-rivetted in. |

|

| and the arm rest stiffeners were popped on the upper line and squeezed at the back. |

|

| The side skin locations were shot / bucked OK and the resulting arm rests are real sturdy - a recommended solution if you want it. |

|

| One of the strange things with the second QB fuselage were some of the oddities. Whilst the Czech lads seem to be fairly uniform on what is done / not done, the Philippines lads seem to be a little schizophrenic - one side of the fuselage has the upper rivets missing. |

|

| The other has them installed. I have no idea why they wouldn't do the same on both sides. I'm guessing the slider might need something slightly different to the tip-up, but not side to side. We had to sort a creative bucking bar to do these locations but not too bad otherwise. |

|

| Whilst we were in the bucking mood, we also sorted the forward rivets. The skin closed up significantly to the longeron during the process. |

|