Fri 05 May 2006 |

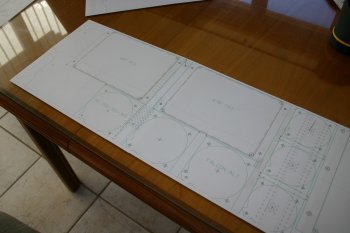

| Got to the point where I have to make some real decisions for the panel. I've proven the process for the various parts that I want to fit - now it is layout. Spent a few more hours refining the layout in CAD, then printed it all out and got the dimensions sorted. |

|

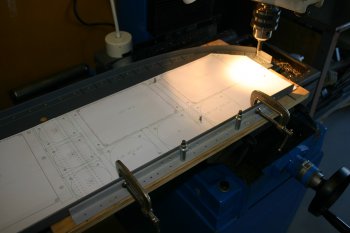

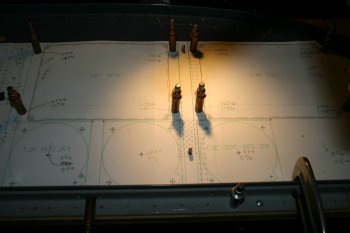

| Then mounted the panel up on the wood surface, including registration pegs so I can re-locate as needed. The main panel will be done in 'two' halves and then the outboard bits, center middle, and upper edges will need to be done seperately. |

|

| I started by going around the LHS mounting locations, most are #6 screws. Something that took quite a bit of time was working out the 'fudge factor' for the table lead screws. They are pretty accurate but have up to about a 5% error, which in a 80cm side-to-side is nearly 8mm. Lots of calculations and then checking and re-checking. |

|