Sat 07 April 2007 |

| I did some rough shaping / sanding of the cowl corners and the plugs look like they should work well. After the concern from yesterday the cowl halves actually split very well. I ran a knife down the break lines and the prized the parts apart - then just an edge that then just needed more tidying and sanding. Slow process but needed. |

|

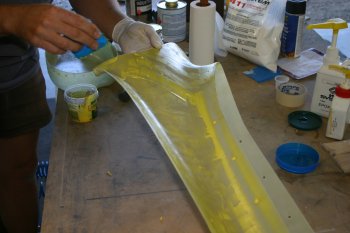

| Also did another batch of micro-balloon resin mix, this time adding a little acetone to help it flow. Surfaced the inside of the filtered air box which had some dry areas and nicks in it and then went onto other fairings. |

|

| The turtle deck fairing is strange floppy piece and hard to sand due to all the compound curves. Hopefully the skimming worked ok and I won't have too many ridges. |

|

| Meanwhile Dad continued with the rear plates for the spinner. One of the challenges is getting the right location for the gap plate to meet up with the fibreglass spinner. |

|

| A second attempt was made and seems to be more promising. |

|

| Current state of play - next step is to mate the metal and spinner parts then the final clearance hole for the prop can be finished on the bench. |

|