|

|

|

| Home | Research | Delivery | Empennage | Wings | Fuselage | Finish | Engine | Electrical | GRTDecode | Previous|Next|Latest |

| Preparation | Delivery | Inventory | Packing | Supporting Parts | Airport Move | |

Supporting Parts | |

Wed 24 December 2003 | |

| Constructed leg stands to attach to the shipping spar butts. Still left todo is adding an axel and wheels to provide a easy method of moving the Fuselage around the shed.

|  |

| The fuselage is now level in both longitudinal and lateral axis when on its new stands. The Smart level is a great bit of equipment. |  |

| Added a protective wooden top for the rear trestle that the tail cone sits on. Might think about a shaped support at some point. |  |

Thu 25 December 2003 | |

| The interim 'under carriage' is done. Wheels can go on and off fairly easily which will help create some space in the shed to be able to unpack all the other crates and complete the inventory process. |  |

Fri 26 December 2003 | |

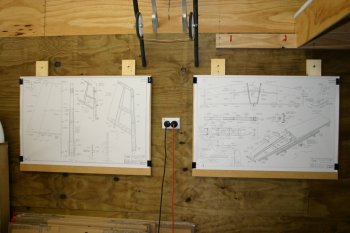

| Knocked up a couple of boards to take the plans that will take clips around the edge and can be hung on the side wall of the shed. |  |

Sat 03 January 2004 | |

| Sorted a temporary air line solution to get us going. The new compressor will be going outside in the longer term, but we need to sort a hard standing outside first. | |

Mon 02 February 2004 | |

| I spent the afternoon designing and building a frame for holding parts for spraying. It has a piece of rabbit fence across the front and is designed to stand almost upright. |  |

| The finished product. The reason it is on the trailer is we can then move the parts from the spraying area out into the sun for drying easily (also undercover if it looks like rain - but we don't get much of that here generally). |  |

| I also made a load of these little hooks to hang the various parts on. |  |

Tue 02 March 2004 | |

| In the morning I had some house keeping tasks and for the afternoon / evening I started on a new bench. The frame work is steel angle. Just lots of measuring, setting of jigs and drilling. |  |

Wed 03 March 2004 | |

| I continued with the bench making process, adding lower stiffeners and spacers for the upper cross members. I skived off early after lunch for some R & R with Mum and Dad (water skiing on the lake.....) |  |

Thu 04 March 2004 | |

| First task was to complete the bench frame work. This included all the wire-brushing and cleaning so that tomorrow I can practice spraying using the air-gun before being let loose on aircraft parts. |  |

Fri 05 March 2004 | |

| The afternoon was a training session for me with the real spray-gun. This is a another new skill set for me. Dad setup the hardware during the morning and the primer (mixed for the push tubes) was then filtered for the spray gun. |  |

| Then I was let loose on the bench legs for practice. I have to say, given a choice 'next time' I would setup the spray-gun much earlier in the project. The rattle cans are convenient (particularly the lack of clean up) but the coat is much thinner (less weight) and I found easier to apply with the spray-gun. The spray gun turns the chore of priming into something I think I might quite enjoy...... |  |

| The primed bench legs out in Sun Mark 4. An early finish with visitors from the UK, out doing the social thing. |  |

Mon 08 March 2004 | |

| A late start as some house keeping tasks had to be completed this morning. First task was to finish spraying the bench legs. |  |

Tue 09 March 2004 | |

| First up was completing the new bench. Traditional Morgan build, it will outlast the plane and probably all of us....... |  |

| A re-organisation of the shed was needed to make space for the new addition. Much easier to work on with room for our legs. |  |

Tue 16 March 2004 | |

| Dad spent some time sorting the band saw into the vertical table position. Some modifications were need to the table. |  |

Wed 17 March 2004 | |

| First up Dad changed the blade on the band saw. The new one is MUCH better. It is a bi-metal variable pitch blade - and goes through AL like butter. Worth the time and effort to get a suitable blade. |  |

Fri 03 December 2004 | |

| A more sturdy, low level platform has also been made to support the fuselage. |  |

Fri 10 December 2004 | |

| |

| Home | Carl Morgan | Previous|Next|Latest |