Sun 26 December 2004 |

| I helped Dad with the gear weldment bolts - a bit tricky to get to and time consumming. |

|

| Several of the lower AN4 bolts seem a bit short, we replaced the main inboard lower weldment bolts with 13's and used a -L washer on the strut. |

|

| We still have a problem with the inboard most lower bolts, the weldment prevents the bolt head seating properly. Options include heavily shaped washers, shaping the bolt head or weldment shaping. Not sure of the best option at the moment. |

|

| Whilst the wings were on, I put the wing fairings back on and marked the 3/16" line for later trimming. The lower aft most nutplate location is going to be real difficult but I'm waiting until I have more space under the fuse (when the undercarriage is on) before sorting it. |

|

| An observation that with the gear weldments tightened up it doesn't actually sit on the lower skin, there is about 1/16" gap. The hole could be tuned further but easy to say after the event. |

|

| Dad continued with the VS mounting. The main challenge was marking the locations for the attach bolts, why VANs doesn't get you to pre drill these with the spar on the bench beats me! |

|

| We then pilot drilled the VS on the drill press. |

|

| The 'precision' washer super-glued in place. |

|

| After remounting the VS for drilling of the rear bulkhead, opened up for the 3/16 bolts. The bulkhead was then removed and the tie down bar drilled. |

|

| Meanwhile I worked on the forward cockpit covers. In particular the airflow pump bracket is basically too big for the gap between the floor stiffeners. I think the problem is actually the floor stiffeners, if you are a slow builder, make sure it is a clean 8" gap between the inside of the angle stiffeners. |

|

| I decided on a slightly different mounting option and removed the flange of the original mount. |

|

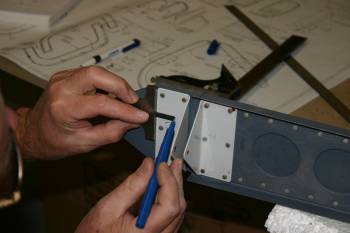

| I then trimmed the standard cover by removing the center section. |

|

| Corner holes and snips were the simplist option. |

|

| After trimming and shaping, I remounted the parts and match drilled the two parts together. |

|

| It all came out OK, probably use AD4 426's for the actual mounting, need to prime the parts first. |

|

| After dinner I rigged the main and nose wheels. Hopefully we can get the fuse onto the real gear so that brake lines can be rigged. |

|