Thu 29 September 2005 |

| Half day today, starting with a refinement of the cowl / baffle gap. A bit more of the clay method - works really well. |

|

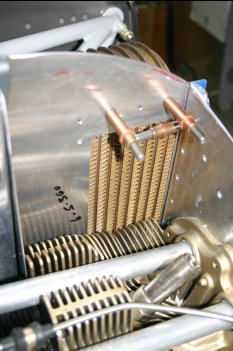

| Dad then went onto the oil cooler location / cut out. |

|

| As an experiment for future requirements, we tried using the milling drill for a rectangular hole. Starting with precision corners. |

|

| And then using a router cutting bit and moving the work on the screw threads. |

|

| The end result - works quite well, the direction of the cut and lots of lubrication are needed to get a clean edge. The lower edge of the cooler is about 3/4" lower than the top of the #4 cylinder. |

|

| The top of the cooler mount will need a bit of trimming and we are still debating about adding a .040" spacer between the side and rear baffles. |

|

| I continued working on the baffles and the front RHS baffle angle. The instructions mention a mini angle section 10S but no details of size / shape / direction. I ended up going for a single brace which seemed to work OK - I might still beef up the join on the outside, but I'll review once any plenum structure has been completed. |

|

| The end result after some trimming and drilling.

More gap between the cowl and the baffles will be needed but I'll wait until later.

I'm also tempted to make a fibreglass smoothing entry duct to help with the transition between the fabric seal and the AL baffles. |

|