Thu 20 April 2006 |

| Continuing with the panel milling - we used a 3mm bit. Boelube was used as a lubricant, that worked for the first one and half sides - then the bit broke! Too small (and possibly not enough lube). |

|

| We switched to a 1/4" mill and continued, the center section was cleco'd down and we used straight turps as a lube - worked better. |

|

| The result - a reasonably clean edge but still needed a bit of file work to get rid of the sharp burrs. |

|

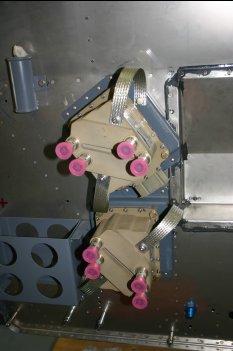

| The mock up in the aircraft. The next questions are based around the canopy frame and where is comes down to, this is about as low as the MFD can go, although the switches can move a little. More prep work to complete first and maybe the new .040" forward skin before re-mounting the canopy. |

|

| Flipping the mockup panel to the RHS, I laid out the Garmin stack location. Same deal, 1/4" drill and then milling the rectangle. A few little problems with the exact mill size (slightly less than 1/4") but looing promising. There will be a small gap around the stack if I use the recommended 6.3" width - I guess that is why we are doing the mock up..... |

|

| Dad did a number of 'bits' but started seriously looking at the ground straps for the FADEC / batteries. Looks like we were short shipped 2 long grounding braids from AeroSance - but shouldn't be a biggy. |

|