Wed 12 October 2005 |

| Dad continued with the test run for the baffle filler. By this point we had worked out the stress relief holes were in the wrong location. The distance from the bend line to the resulting outside surface is 3/32". |

|

| The alignment of the front surface is based from the rear inboard baffle. |

|

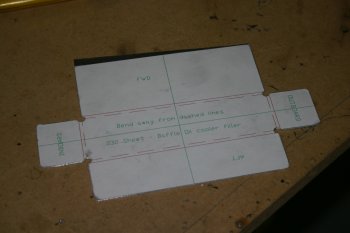

| The first attempt - pretty close, a bit short of material on the aft attach plate. |

|

| A quick modification of the CAD layout - and try again. |

|

| This time everything fitted much better. The upper 4 AD4 rivets that hold the oil cooler bracket also now go through to this mini-baffle. The lower surface is in line with the top of the oil cooler entry and the front surface is in alignment with the rear baffle that is further inboard. |

|

| I continued with the plenum work. The RHS forward support was first up - same as yesterday - funky twists, angles and trimming. |

|

| Then sorted the forward brace, slightly tricky as access for the drill is very limited. |

|

| The front braces needed a bit of shaping and I drilled / clecoed them to the front baffles. These will provide the forward support for the centre section. I'm planning on a doubler plate to provide strength towards to front edge. It is a 1" wide strip of 0.20". IF you are going down this route - you don't want holes / clecos here - less is better - I got over keen. |

|

| The I sorted the LHS inboard brace. This is another piece of 0.63 angle, with some 'clever' cuts at the ends. A slight twist may be needed but I'll wait until the upper skin surface is sorted. |

|