Thu 05 February 2004 |

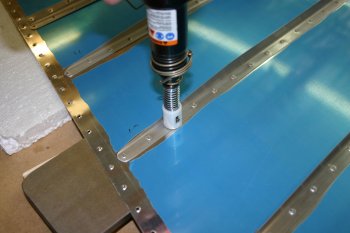

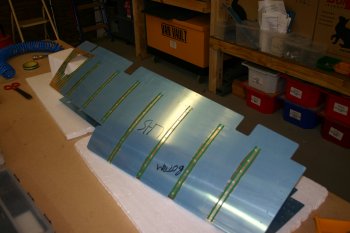

| Another day, another set of skills to learn and work out. At this stage in the project lots (most?) things are new to us. Today we started back riveting. The rudder and elevator surfaces use very thin sheet AL (0.020" - 20 thousandths of an inch) these then have stiffeners attach to them to strengthen the skin surface. To get a nice flush finish of the rivet a large steel plate is used to 'hold' the rivet flat with the skin surface. The shop head is then 'hit repeatedly' with the rivet gun to fix it in position. |

|

| Some assistance to hold the rivets in place is 'rivet tape'. Seem quite an expensive form of sticky tape, but I have to admit it seemed to work well. |

|

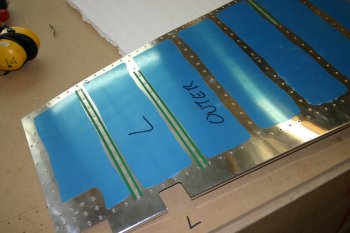

| I started with the L rudder skin, all fairly simple and straight forward once I got setup. I found about 40 psi for ~3/4 second seemed to work well. |

|

| Then the same deal with the right side skin of the rudder. |

|

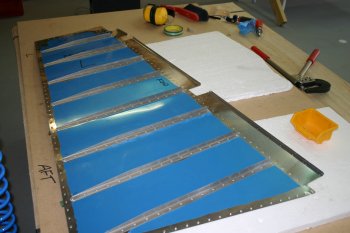

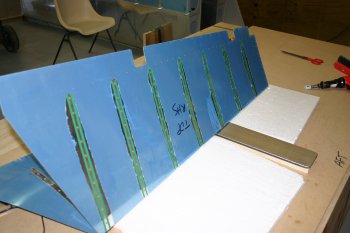

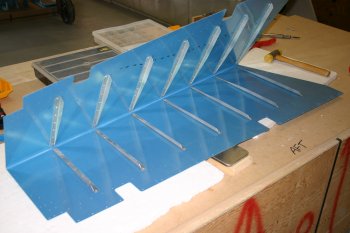

| Then I moved onto the elevators skins. The stiffener attachment step has to be completed before the surface is 'squashed' which is needed to complete the rest of the match drilling and preparation. The stiffeners now being primed meant progress could be made. I decided to rely on the ALCLAD on the skins for skin protection / anti-corrosion. |

|

| A large proportion of the rivets are easy. The final two aft most rivets (at the apex of the bend) of the second side are very difficult to get to and I thought seriously about using a bucking bar. Before I deviated from the instructions I sent a query to the SoCAL list to see what the guys had to say. |

|

| Meanwhile I got on with the other elevator skin. |

|

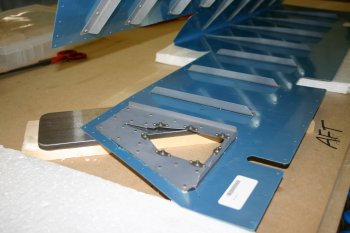

| Dad sorted the elevator electric trim stiffener. It needed dimpling and the platenuts fixed. |

|

| The finished elevator. The theme from the list was just do as you are told. Back rivet them all, the skin will bend that far and it won't cause any permanent damage. I now concur with this opinion and found all it really required was a little more confidence on the man handling of the material.

Overall, not a bad day, results are pretty good. Two additional things learnt - The rivet gun uses more lubricating oil than the other tools and 'stalls' if it gets too tight, a little extra oil and high pressure to get it going and everything was fine. Secondly - Don't over drive the rivets on stiffeners, it will result in a slight deformation of the skin (however it isn't too serious) - don't ask me how I know!

With the above knowledge, I suggest you set the top skins of the elevators FIRST, then the lower skins. This means any 'dodgy' over driven rivets will be on the lower surface and will not be as visible or bug you quite as much. |

|