Fri 09 September 2005 |

| Today was a big day from a morale perspective. We planned to mount the engine. The Lord mounts have upper / lower & fore and aft parts. I just laid everything out carefully and then got them checked. |

|

| The engine mount is something multiple people have multiple ideas about.

The 'VANs method' is to locate the lower points first and pull the egine back into the top points.

The 'Mattituck / Cal method' which I saw demonstrated in July in New York is to do the upper points first,

then drop the bottom ones in. It was a toss-up between them, but I went with the 'Cal' method as I had

seen that demonstrated. |

|

| Get the fuselage level and the engine also level. Push up to the mount and position the top bolts. |

|

| Then 'wiggle' the top mounts and get the bolts started. |

|

| Then position the lower mounts and lower the engine into the slots. The lower bolts were then drifted quite easily. |

|

| Then tighten all the bolts and it is done. |

|

| The finished result - about 30 mins start to finish. I'm sure it can be a real pain, but having seen it done before definitely helps. |

|

| Next I started looking at the filter air box (FAB). Mainly just deburring / understanding as the lower cowl is needed before much alignment can be completed. |

|

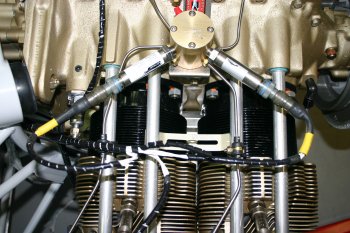

| I also re-visited the FADEC harness challenges. |

|

| The major problem is the Fuel pressure sensor cables. They are very tight and restrict all the other components. I think probably the harness will need spliting. |

|

| The lower section is fine - Manifold pressure and temp sensors are fine. The top of the FAB does look very low. The cowl is needed for a number of alignment things, I think that might be a 'soon' job. |

|

| One thing to remember - without the nose wheel / main gear installed - you need a significant amount of weight on the tail to balance the engine. |

|